A revolutionary fleece made from wood fibers

Long pointed out, as a source of extremely polluting microparticles, the right fleece jacket, warm, light and quick to dry, can finally find its place in our backpack. The solution ? Cellulose fibers made from sustainable eucalyptus and beech fibers certified as 100% biodegradable. The culmination of years of research for the German VAUDE, specialist in mountain clothing, a pioneer in this field.

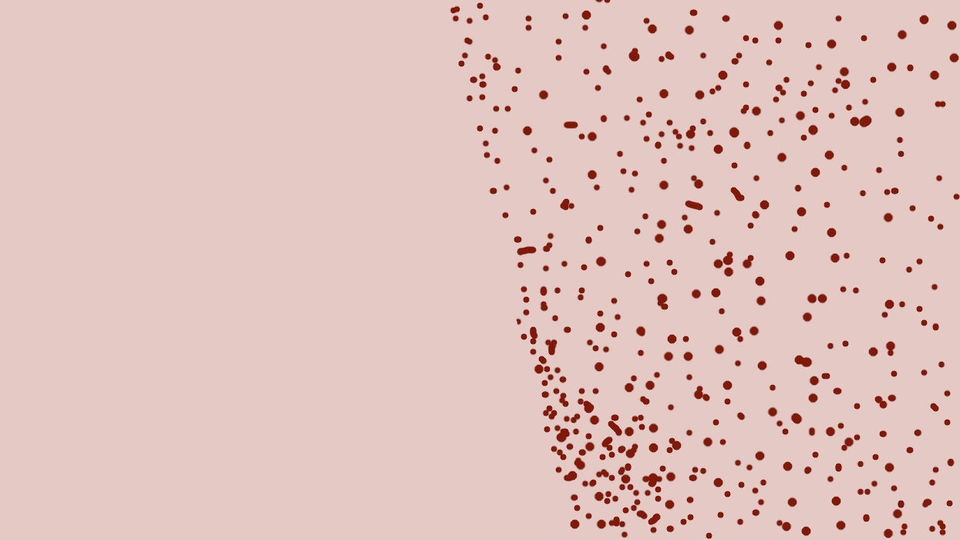

More than 12 million tons of plastic waste ends up in our oceans each year, experts say, mostly in the form of tiny fragments, called microplastics. Measuring less than 5 mm, they are often invisible to the naked eye, and come from a variety of sources, including more than a third of the synthetic textiles used to make clothing. And the trend does not seem ready to weaken when we know that we buy on average 60% more clothes than 15 years ago... by keeping them half as long! At this rate, by 2050 there will be more plastic than fish in the world's oceans, according to a report published by the Ellen MacArthur Foundation.

But what makes microplastics so problematic is that not only are they extremely durable and take hundreds of years to break down, but they usually float somewhere between the surface and the bottom where marine animals take them for food. Moreover, in the food chain, these residues that accumulate in larger animals whose development is affected, also end up in the food we eat, promoting cancer and endocrine disruption in humans. An invisible but terribly devastating pollution to which the outdoor industry contributes, a large consumer of synthetic fibers such as polyamide or polyester. In particular for the manufacture of fleece, a basic outdoor garment, highly appreciated for its softness, warmth and ease of maintenance, which has become extremely popular over the past forty years.

Fleece, a nightmare for scientists

Victim of their success, fleece products have also quickly come into the crosshairs of scientists, who now designate it as the worst offender , according to the study by the Bren School of Environmental Science and Management at the University of California, Santa Barbara. From their fluffy surface, a multitude of microplastic fibers escape over the washes, which are only partially filtered by wastewater treatment plants.

A problem that does not leave indifferent the German VAUDE, one of the most demanding in the textile industry in terms of the environment. Since its creation in 1974, the equipment manufacturer has quietly accumulated advances in research on its environmental impact. A pioneer of an eco-responsible lifestyle, the brand launched the first trials in the mid-1990s to fully recycle the technical clothing of outdoor athletes, within the Ecolog-Recycling network. In 2001, it was the first in the outdoor industry to support and use the very rigorous “Bluesign” label. Eight years later, in 2009, it went even further and created its own "Green Shape" quality label certifying not only the raw textile material, but all the constituent elements of a jacket. Logically, in 2015, it signed the Greenpeace Detox Commitment, thus committing to eliminate by the end of 2020 all polluting substances from its entire supply chain and to manufacture all its collections without using PFCs.

Therefore, as a manufacturer of fleece garments, VAUDE could only feel responsible and actively seek solutions to prevent the proliferation of microplastics in the environment. What the brand has done by attacking the problem at its root: namely the materials used, explains Antja von Dewitz, general manager of the brand. "Either these materials shouldn't release microfibers, or the ones they do release should be biodegradable," she says. The German manufacturer therefore actively participated from September 2017 to March 2021 in a major research project "TextileMission", funded by the German Federal Ministry of Education and Research (budget of 1.7 million euros), together with partners from the sporting goods industry, universities, WWF Germany and washing machine manufacturers Miele and Henkel. "We are aiming on the one hand to optimize the technology of wastewater treatment plants with filters, and on the other hand to develop textiles with significantly lower particle emissions", explained Hilke Patzwall, CSR Manager at VAUDE, at its launch. . Research is also underway around biobased and biodegradable fibers as an ecological alternative. »

A hyper-functional jacket in 100% biodegradable fibers

In partnership with the Italian producer Pontetorto, VAUDE has thus become the first outdoor equipment manufacturer to develop a very soft fleece material containing TENCEL®< /sup> on its inner side. Its specificity: the microparticles that enter the global water circuit are completely biodegradable in seawater. Composed of 100% eucalyptus and beech wood from sustainably managed and FSC (Forest Stewardship Council) certified plantations , this fiber also offers excellent functional properties. Presented to the public in November 2017, during the Performance Days textile trade fair organized in Munich, this innovation won the Eco Performance Award, one of the most prestigious environmental awards.

This new material was used for the first time in the fully sustainable "Green Shape Core Collection", presented in 2018. VAUDE has thus established itself as the first brand in the outdoor industry to develop a fleece environmentally friendly: the Miskanti Fleece Jacket. A jacket with a recycled polyester exterior and TENCEL® interior. From an environmental point of view, this has several advantages. To know :

We could reduce the amount of microparticles by 80%

Result, a fully biodegradable natural fiber fleece perfectly suited to outdoor activities. Soft, breathable and warm, it wicks moisture away from the body quickly and effectively, keeping you dry and neutralizing odors without the addition of additional chemicals. The growth of bacteria being inhibited by the material itself. Since then, the VAUDE collection has greatly diversified, with the arrival of jackets such as the Croz II fleece, the Valua fleece, or even a model for children, the Kids Faunus. And, more recently, the Elope fleece for women, containing 62% recycled polyester and 38% wood cellulose fibres.

A revolution still in progress – the development of fleeces in wood fibers continues with a particular attention paid to the different grammages – which is accompanied in parallel by radical changes for the brand. The German manufacturer did not hesitate to remove almost all of its intermediate and thick fleeces from its product ranges in favor of micro down jackets. Because, she explains, “in the case of down jackets, the free fibers are trapped in the compartments of the textile, which prevents the detachment of microplastics”. To date, in the outdoor sector, VAUDE is the only brand to invest so much in this type of research, aware that a global approach could make it possible to reduce by 80% the quantity of microparticles generated by the textile industry failing in our oceans. It remains to be seen whether other brands will follow...

To discover all the VAUDE wood fiber collections, visit www.vaude.com

- Themes:

- Environment

- Equipment

- Textile

- Vaude< /dd>