The green side of whey Get breaking news alerts from Le Devoir

Quebecers love their cheeses. And the producers of the province return it well, combining without hesitation the flavors of the country and respect for the environment. Second of three texts on the nature of these products from here.

Quebec producers are increasingly concerned about the environmental footprint generated by the preparation of their cheeses, by adopting strategies that limit waste and revalorize the by-products of their manufacture.

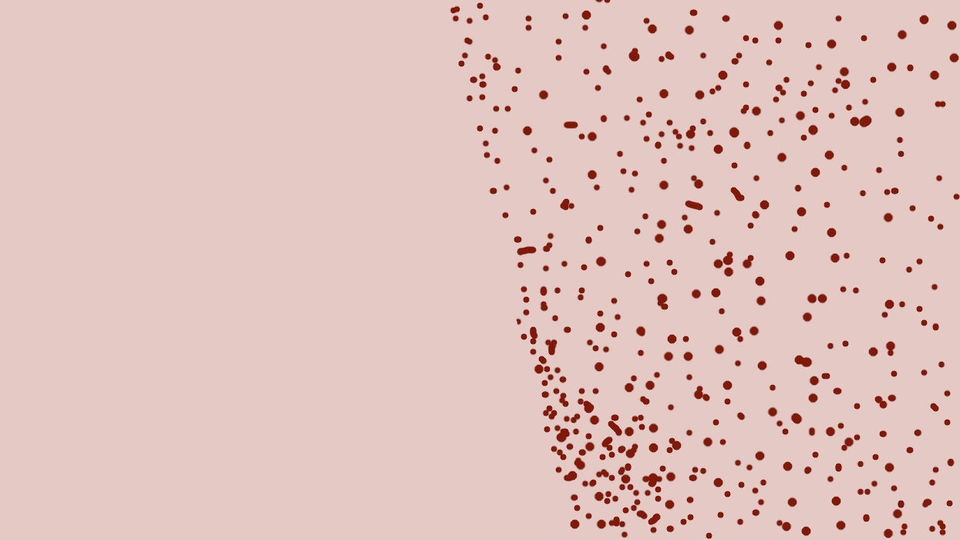

The production of one kilo of cheese alone generates up to nine liters of whey, also called whey, the liquid that remains after the milk has been transformed into curds.

Until the early 1980s, "we threw it away, we didn't even ask ourselves the question," says Steve Labrie, director of the Center for Research in Dairy Science and Technology (STELA) at Laval University. . Things have changed since then: we realized that whey had an important value, both nutritionally – it is rich in protein and lactose – and in terms of the environmental footprint, notes the scientist.

Also read

The secret of Quebec cheesesCurrently, a good part of the whey goes to animal feed, particularly that of pigs and calves. But it is also used to feed humans: once transformed into powder by companies that collaborate with cheese makers, it is incorporated into several foods – pastries, cookies, puddings – to enrich their taste and nutritional value.

Whey has also become a natural product very popular with athletes: thanks to ultrafiltration, it can now be made into a real protein concentrate, explains Yves Pouliot, professor at Laval University.

The lactose sector

Other companies then promote lactose, the sugar in whey. It is used by infant formula manufacturers, but also by the pharmaceutical industry. “When we press the ingredients of a medicine into a tablet, we often use lactose to glue the particles together. Lactose has the advantage of being inert: it does not react with anything else”, illustrates Professor Pouliot.

However, transporting the whey from the cheese dairy to the places where it is processed remains a big problem, points out the milk processing specialist, because the raw substance is made up of 95% water.

"It doesn't make sense to carry it as it is. To remove the water, we therefore turned to reverse osmosis, a filtration process used in many sugar bushes and in some domestic water purification systems. The process basically involves passing the whey through a filter that blocks everything but water molecules. Large cheese dairies have already started to do this and reuse the extracted water in the maintenance of their equipment, underlines the researcher.

The resulting lactose concentrate can then be distilled to make beer or spirits. It can also be converted into biogas and thus provide a source of energy.

Lactose can also be transformed into lactulose, a substance that helps digestion and is very popular in Asia.

Other challenges

In another vein, researchers at Université Laval have also developed software that can help Quebec cheese producers use as little water and energy as possible. However, the question of milk pasteurization remains to be resolved: the double-walled heating systems used today require a lot of energy. It is therefore on the recovery of energy and the search for alternatives to heat treatment that we are working.

However, processing represents "only 15 to 18% of the entire environmental footprint of milk", emphasizes Professor Pouliot. "For each liter of milk, the carbon footprint is 80% on the farm: the feed of the cows, the methane they release, the manure they generate..."

The fact remains that “thanks to the efforts that have been made in recent years, Quebec milk is among the best” in this regard, he says.